Time is money, and we save you both. We don’t mess around when it comes to precious time, and we offer the highest quality aluminum products that other companies don’t stock. We make a point of keeping products on-hand that other companies will not, because it is our goal to make your experience with us painless and fulfilling. Visit our website or call us today to learn more!

At Alliant Metals, we take pride in being a trusted source for high-quality aluminum products that meet the demands of a wide range of industries. Our work revolves around providing precision-cut aluminum in the form that best serves our customers, whether that means sheets, plates, bars, or custom-cut shapes prepared to exact specifications.

At A-1 Alloys, we take pride in being a trusted partner in the aluminum industry, providing customers with high-quality materials, precise processing, and dependable service. Our focus on aluminum allows us to deliver a wide range of grades, forms, and sizes to meet the unique needs of industries that rely on strength, durability, and lightweight performance.

At Champagne Metals, we are dedicated to delivering premium aluminum products and solutions designed to meet the diverse needs of our clients. Our expertise spans a broad spectrum of aluminum offerings, including extrusions, fabricated components, and custom profiles tailored to specific requirements.

More Aluminum Tubing Manufacturers

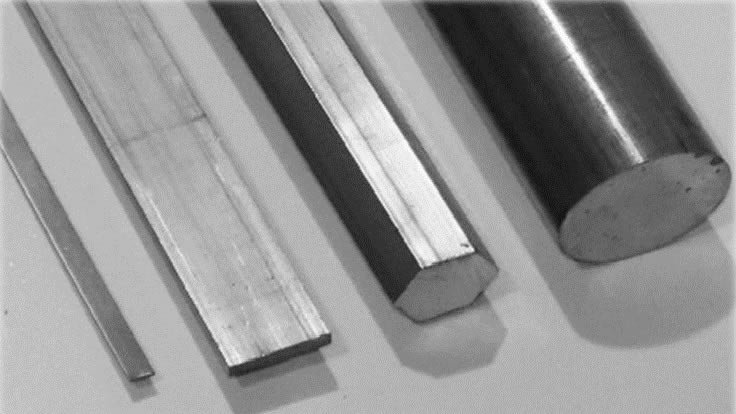

Aluminum tubes may be cylindrical or square in shape, and they vary in terms of outside diameter (OD), inside diameter (ID) and alloy type. Aluminum tubing can be formed by a number of processes, including roll-forming, extrusion and CNC-machining. Aluminum tubing is widely used in the aerospace, chemical and food processing industries, although it has also found use in automotive manufacturing, medical equipment production and a variety of other fields.

Aluminum tubes are important throughout industry, commerce and consumer products contexts. Industrial manufacturers make extensive use of aluminum tubes and pipes, for the transportations of fluids or free-flowing solids in large quantities. Commercial operations such as greenhouses may use bent aluminum tubes as structural elements, and farms may use aluminum tubes for irrigation purposes. Many consumer products also involve aluminum tubes in some way. For example, thin, light-weight aluminum tubes are frequently used in the construction of outdoor furniture.

Important considerations when selecting aluminum tubing include pressure rating, maximum bend radius and temperature range. Aluminum performs very well at low temperatures but may fail at higher temperatures unless it is tempered. Aluminum tubing may also be anodized, which adds to the resistance capabilities of the outer coating and makes it possible to dye the aluminum. Anodizing is the process of endowing the surface of a metal with an oxide layer. This oxide layer makes further oxidization (another word for corrosion) of the metal impossible.

Because aluminum is considered to be naturally corrosion resistant, anodized aluminum is very corrosion resistant. Aluminum tubing can benefit from the anodization process, especially when it is employed in settings where it is likely to be exposed to corrosive substances like salt water. Aluminum tubing, pipes, sheets, rods, plates and bars are among the most common shapes offered by aluminum suppliers. Each variety is constantly in demand across industrial and commercial contexts.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services