Time is money, and we save you both. We don’t mess around when it comes to precious time, and we offer the highest quality aluminum products that other companies don’t stock. We make a point of keeping products on-hand that other companies will not, because it is our goal to make your experience with us painless and fulfilling. Visit our website or call us today to learn more!

At Alliant Metals, we take pride in being a trusted source for high-quality aluminum products that meet the demands of a wide range of industries. Our work revolves around providing precision-cut aluminum in the form that best serves our customers, whether that means sheets, plates, bars, or custom-cut shapes prepared to exact specifications.

At A-1 Alloys, we take pride in being a trusted partner in the aluminum industry, providing customers with high-quality materials, precise processing, and dependable service. Our focus on aluminum allows us to deliver a wide range of grades, forms, and sizes to meet the unique needs of industries that rely on strength, durability, and lightweight performance.

At Champagne Metals, we are dedicated to delivering premium aluminum products and solutions designed to meet the diverse needs of our clients. Our expertise spans a broad spectrum of aluminum offerings, including extrusions, fabricated components, and custom profiles tailored to specific requirements.

More Aluminum Suppliers Manufacturers

Aluminum Suppliers: A Complete Guide to Selecting, Sourcing, and Using Aluminum Materials

Metalworking and manufacturing businesses across diverse industries rely heavily on aluminum suppliers to provide high-quality aluminum products and raw materials. From basic aluminum shapes and custom extrusions to specialty aluminum alloys, suppliers deliver essential materials such as aluminum sheets, rods, bars, and plates that serve as the foundation for countless applications. Aluminum is a light, silvery-white metal prized for its bendability, corrosion resistance, and impressive strength-to-weight ratio. Commonly used items that utilize aluminum include beverage cans, foil, cookware, window frames, beer kegs, automotive parts, aerospace components, and a wide range of industrial equipment.

Aluminum's popularity in manufacturing is due to its unique set of material properties. It is easy to cast, fabricate, and form, features low density, is non-toxic, and boasts outstanding corrosion resistance and high thermal conductivity. Aluminum is also non-magnetic and non-sparking, making it suitable for specialized environments such as electronics manufacturing and chemical processing. While pure aluminum is not particularly strong, it becomes highly durable when alloyed with elements such as silicon, manganese, magnesium, and copper. These aluminum alloys are lightweight yet strong, making them essential for critical applications in the aerospace, automotive, construction, and marine industries.

Aluminum’s excellent electrical conductivity makes it a popular choice for transmission lines and electrical wiring. Pound for pound, it is nearly twice as conductive as copper and typically costs less, offering significant advantages for large-scale infrastructure projects. The combination of lightweight design, cost efficiency, and versatility makes aluminum a preferred material for engineers, designers, architects, and procurement professionals alike.

How to Select an Aluminum Supplier: Key Considerations for Buyers

Finding a reliable aluminum supplier who consistently delivers top-quality aluminum at competitive prices is crucial for companies in sectors that depend on aluminum products. The quality, consistency, and performance of your final products are directly influenced by the underlying materials your supplier provides. Below, we explore the most important factors to consider when choosing an aluminum supplier for your business needs.

What Should I Look for in an Aluminum Supplier?

- Range of Products and Materials: Leading aluminum suppliers maintain strong relationships with reputable aluminum producers and mills who adhere to strict quality standards and utilize advanced manufacturing processes. Look for a supplier that offers a broad portfolio, including aluminum sheets, aluminum tubing, aluminum plates, bars, rods, extrusions, and custom shapes. Availability of specialty alloys and tempers is a plus for buyers with unique engineering requirements.

- Certifications and Compliance: Ensure your aluminum supplier meets industry certifications such as AS9100D for aerospace, ISO 9001:2015 for quality management, ISO 14001:2015 for environmental responsibility, and ISO 50001:2011 for energy management. These certifications reflect strict adherence to manufacturing and supply chain standards.

- Manufacturing Capabilities: Evaluate suppliers based on their ability to provide value-added services such as aluminum cutting, shearing, CNC machining, custom fabrication, and finishing (anodizing, powder coating, etc.). High-capability suppliers can help you streamline procurement and reduce lead times.

- Inventory and Delivery: Choose a supplier with a well-stocked inventory and efficient logistics. Timely order fulfillment, flexible shipping options, and on-time delivery are essential for minimizing downtime and keeping projects on schedule.

- Competitive Pricing and Cost Transparency: Request detailed quotes and compare prices for bulk aluminum purchases, custom orders, and ongoing supply agreements. Reputable suppliers will provide clear, upfront pricing and help you optimize your material costs.

- Customer Service and Support: Top aluminum distributors prioritize responsive customer service, technical support, and clear communication throughout the ordering process. Look for suppliers who offer educational resources, fast order confirmations, and proactive assistance when issues arise.

- Product Expertise and Technical Guidance: Your supplier should possess in-depth knowledge of aluminum grades, alloys, and processing methods. Expert guidance on selecting the right material, temper, and finish can help you avoid costly mistakes and achieve your project goals.

Customer Service and Performance: Why Do These Matter?

Responsive, knowledgeable customer service is a key differentiator among aluminum suppliers. Good suppliers pay close attention to detail regarding delivery dates, provide clear communication, and are proactive in resolving any issues that arise during the ordering and delivery process. A well-stocked inventory and a user-friendly online ordering system can make it easier for customers to research, compare, and purchase aluminum materials. Additionally, suppliers who invest in educational content help customers make informed decisions regarding alloy selection, design requirements, and application suitability.

Order accuracy, fast turnaround, and hassle-free claims processing are essential for building trust and long-term business relationships. When evaluating suppliers, ask:

- How quickly can orders be processed and shipped?

- What is the typical lead time for custom or bulk aluminum orders?

- How are product damages or discrepancies handled?

- Is technical support available for product selection and engineering questions?

Product Expertise: How Important Is Industry Knowledge?

Leading aluminum suppliers employ industry experts who understand not only the properties of aluminum, but also the requirements of key verticals such as aerospace, automotive, electronics, construction, and marine manufacturing. This expertise allows them to provide tailored recommendations based on your intended application, whether you need lightweight structural components for an aircraft, corrosion-resistant alloys for marine environments, or thermally conductive materials for heat sinks and electronics.

In addition to product knowledge, a reputable aluminum supplier will be familiar with best practices for shipping and storage. Aluminum’s malleability means it can be easily scratched or dented if mishandled, especially when transported alongside heavier metals. Suppliers should use protective coatings and packaging to prevent damage during transit, and advise on storage conditions to avoid contamination and corrosion. For example, aluminum should be kept in clean, dry, dust-free environments and away from moisture or harsh chemicals.

Aluminum Products: Types, Applications, and Use Cases

Modern aluminum suppliers offer a diverse array of products to serve manufacturers, fabricators, and end-users across industries. Understanding the various forms and their typical applications can help you select the best material for your project.

Aluminum Sheet and Rolled Products

Aluminum can be rolled into thin sheet products, which are used extensively in the aerospace, automotive, building and construction, transportation, packaging, and consumer goods sectors. Rolled aluminum sheets are valued for their versatility, ease of fabrication, and broad range of available thicknesses and alloys. Many suppliers also offer custom-cut aluminum sheets and coil products to meet specific project requirements.

Common Applications for Aluminum Sheet

- Aircraft skins and structural panels

- Automotive body panels and heat shields

- Building facades, roofing, and cladding

- Food and beverage packaging

- Signage and display systems

- Consumer electronics enclosures

When sourcing aluminum sheet, ask potential suppliers about their certifications, available alloys, finish options, and minimum order quantities. This ensures you receive sheet products optimized for your specific industry and use case.

Extruded Aluminum: Versatility in Design and Engineering

Extruded aluminum products are manufactured by forcing aluminum through a shaped die, resulting in custom profiles with precise dimensions and cross-sections. This process allows for the creation of complex shapes that offer both structural strength and lightweight performance. Extruded aluminum is widely used for architectural framing, window and door systems, railings, brackets, tubes, and custom industrial parts.

Advantages of Aluminum Extrusion

- Design flexibility for custom shapes and profiles

- High strength-to-weight ratio

- Excellent thermal and electrical conductivity

- Corrosion resistance and long service life

- Cost-effective production for medium to high volumes

Looking for custom aluminum extrusions? Inquire about die design, minimum run sizes, available alloys, secondary operations (such as drilling, tapping, machining), and finishing options like anodizing or powder coating. The right supplier will help you optimize your design for cost, manufacturability, and performance.

Aluminum Plate: Heavy-Duty Performance for Critical Applications

Aluminum plate products are thicker than sheet and are designed for heavy-duty structural and industrial uses. Common applications include aerospace components, marine structures, commercial transportation, tooling, and high-strength assemblies. Leading suppliers offer both standard and custom-cut aluminum plates in a variety of grades, tempers, and thicknesses to suit demanding requirements.

Typical Uses for Aluminum Plate

- Aircraft and spacecraft structural parts

- Shipbuilding and marine equipment

- Heavy machinery, jigs, and fixtures

- Precision tooling and dies

- Military and defense applications

When requesting aluminum plate, specify your required dimensions, alloy, temper, and any secondary machining or finishing needs. Reputable suppliers provide technical support to help you choose the best plate product for your application’s mechanical, thermal, and corrosion resistance requirements.

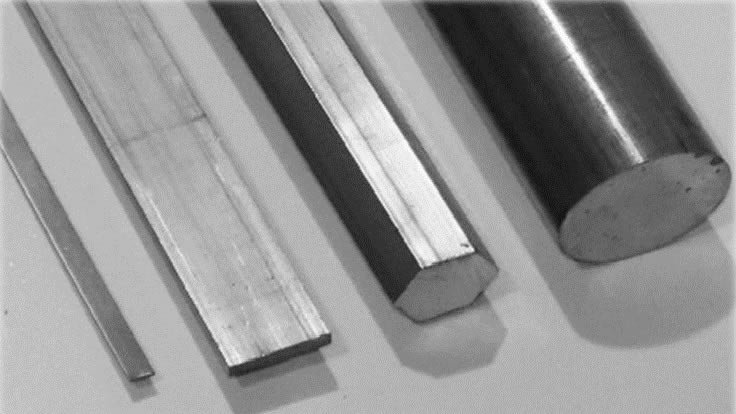

Other Common Aluminum Products and Shapes

- Aluminum Rods and Bars: Used in machining, construction, and manufacturing of precision components.

- Aluminum Tubing: Essential for fluid transportation, structural supports, and heat exchangers. Find aluminum tubing suppliers.

- Aluminum Wire: Utilized in electrical applications, fencing, and specialty fabrication.

- Custom Extrusions and Fabricated Parts: Suppliers offer made-to-order profiles and assemblies for unique design challenges.

Industries Served by Aluminum Suppliers: Who Uses Aluminum and Why?

Aluminum’s lightweight, strength, and corrosion resistance make it the material of choice for a wide range of industries:

- Aerospace: Airframes, fuselages, wing structures, and interior components rely on high-strength aluminum alloys for weight reduction and performance.

- Automotive: Chassis, body panels, engine components, wheels, and heat exchangers benefit from aluminum’s fuel efficiency, crashworthiness, and recyclability.

- Construction: Window frames, curtain walls, roofing, and decorative facades employ aluminum for aesthetics, weather resistance, and ease of installation.

- Electronics: Enclosures, heat sinks, circuit board substrates, and casings utilize aluminum’s conductivity and shielding properties.

- Marine: Boat hulls, decks, and superstructures are built with marine-grade aluminum for corrosion resistance and low maintenance.

- Transportation: Rail cars, trucks, trailers, and shipping containers are manufactured with aluminum for lighter, more efficient transport solutions.

- Energy: Power transmission lines, solar panel frames, and wind turbine components leverage the conductive and structural benefits of aluminum.

Choosing the Proper Aluminum Suppliers Company: How to Compare and Evaluate Options

To ensure the best results when purchasing aluminum materials or products, it is important to compare multiple aluminum suppliers and manufacturers. Our Aluminum Suppliers directory provides detailed business profile pages highlighting each company’s specialties, certifications, capabilities, and contact details. Use the directory to:

- Research companies specializing in the aluminum product type or alloy you need

- Compare certifications, manufacturing capabilities, and product portfolios

- Request quotes directly from manufacturers using our contact forms

- Preview supplier websites to assess their expertise and service offerings

- Use our simple RFQ (Request for Quote) tool to reach multiple suppliers with a single inquiry

Ready to Source Aluminum? Start Here:

- What are the most popular aluminum alloys for my industry? Explore options such as 6061, 6063, 7075, and 2024 for aerospace, automotive, and construction applications.

- How do I choose the right aluminum supplier? Consider experience, certifications, inventory, and ability to handle custom requirements.

- What secondary services are available? Look for cutting, machining, finishing, and logistics solutions that streamline your supply chain.

- How can I reduce costs when buying aluminum in bulk? Ask about volume pricing, just-in-time delivery, and supplier-managed inventory programs.

Frequently Asked Questions About Aluminum Suppliers, Materials, and Procurement

How do I get a quote for aluminum products?

Use our online directory to find aluminum suppliers that match your needs. Click on their profile to request a quote, or use our RFQ feature to contact several suppliers at once. Be sure to specify product type, alloy, size, and quantity for accurate pricing.

What is the difference between 6061 and 7075 aluminum?

6061 aluminum offers good strength, weldability, and machinability, making it popular for general engineering and structural applications. 7075 aluminum is much stronger and often used for aerospace or high-stress components, but is less weldable and more expensive.

Can aluminum suppliers provide custom fabrication or machining?

Yes. Many leading aluminum distributors and service centers offer value-added services such as precision cutting, CNC machining, drilling, punching, welding, and finishing. Specify your project details when requesting a quote.

What certifications should reputable aluminum suppliers have?

Look for suppliers certified to AS9100D (aerospace), ISO 9001:2015 (quality), ISO 14001:2015 (environmental), and ISO 50001:2011 (energy) standards. Nadcap accreditation is also important for aerospace and defense applications.

How do I ensure quality and consistency in aluminum supply?

Work with suppliers who maintain rigorous quality control systems, provide mill test reports, and have a proven track record of reliable deliveries. Ask for references and review their past project portfolio.

What are current trends in the aluminum industry?

Recent trends in the aluminum market include increased use of recycled aluminum, advances in lightweighting for automotive and aerospace, demand for sustainable manufacturing, and development of new high-performance alloys for emerging technologies.

Conclusion: Get the Best Value From Your Aluminum Supplier

Whether you need bulk aluminum sheet, custom extrusions, precision-cut plate, or specialty alloys, choosing a knowledgeable, dependable aluminum supplier is essential for your business’s success. Consider product range, technical expertise, certifications, customer service, and value-added capabilities when comparing suppliers. Use our Aluminum Suppliers directory to connect with trusted manufacturers and distributors who can deliver the quality, consistency, and value your projects demand.

Ready to start your search? Browse trusted aluminum suppliers now and request a quote for your next project.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services