Time is money, and we save you both. We don’t mess around when it comes to precious time, and we offer the highest quality aluminum products that other companies don’t stock. We make a point of keeping products on-hand that other companies will not, because it is our goal to make your experience with us painless and fulfilling. Visit our website or call us today to learn more!

At Alliant Metals, we take pride in being a trusted source for high-quality aluminum products that meet the demands of a wide range of industries. Our work revolves around providing precision-cut aluminum in the form that best serves our customers, whether that means sheets, plates, bars, or custom-cut shapes prepared to exact specifications.

At A-1 Alloys, we take pride in being a trusted partner in the aluminum industry, providing customers with high-quality materials, precise processing, and dependable service. Our focus on aluminum allows us to deliver a wide range of grades, forms, and sizes to meet the unique needs of industries that rely on strength, durability, and lightweight performance.

At Champagne Metals, we are dedicated to delivering premium aluminum products and solutions designed to meet the diverse needs of our clients. Our expertise spans a broad spectrum of aluminum offerings, including extrusions, fabricated components, and custom profiles tailored to specific requirements.

More Aluminum Pipe Manufacturers

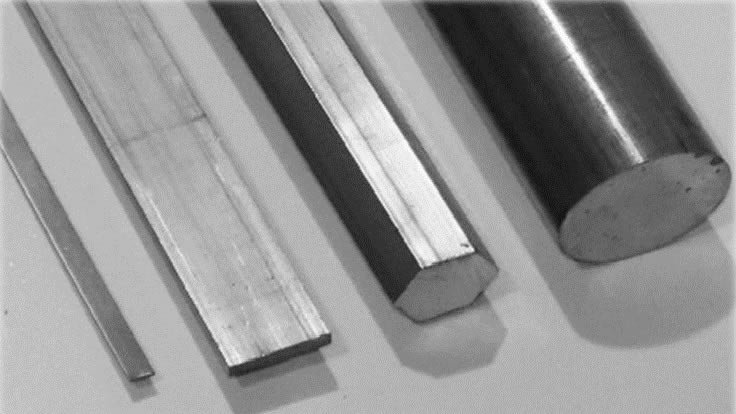

There are several different methods for creating aluminum pipes. All pipes are created using the aluminum extrusion process which utilizes what is called a solid aluminum blank or slug. A set of tools in a die is used to form the pipe by removing material from the center of the blank, leaving a uniform, straight, hollow aluminum tubing shape.

This is the most basic method for manufacturing aluminum pipes. However, further processing can be done to better control the dimensional attributes and improve the strength of the pipe. The drawing process takes the extruded pipe and pulls it through a tool which reduces the diameter of the pipe. Aluminum pipe drawing improves strength, provides a better surface finish, and allows for better dimensional control. When these extra features are not need, however, normal extruded aluminum works just as well as drawn aluminum.

Due to the many inherent qualities of aluminum, aluminum pipes are utilized in all kinds of applications. It can be used in some of the harshest environments due to its exceptional corrosion resistance, and its low density allows it to be used in weight sensitive applications. Additionally, aluminum has excellent thermal conductivity making it useful for heat transfer applications. Aluminum pipes have been used in the automotive and heating industry, finding use in radiators and other heating equipment.

The agriculture industry also makes extensive use of aluminum pipes in irrigation systems. Aluminum pipes provide the necessary durability and rigidity needed to withstand environmental hazards and heavy machinery. Aluminum is also commonly used to make pipe-fittings like couplings, elbows, and tees. The versatility and reliability of aluminum pipes make them ideal for practically any commercial or industrial application.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services