Time is money, and we save you both. We don’t mess around when it comes to precious time, and we offer the highest quality aluminum products that other companies don’t stock. We make a point of keeping products on-hand that other companies will not, because it is our goal to make your experience with us painless and fulfilling. Visit our website or call us today to learn more!

At Alliant Metals, we take pride in being a trusted source for high-quality aluminum products that meet the demands of a wide range of industries. Our work revolves around providing precision-cut aluminum in the form that best serves our customers, whether that means sheets, plates, bars, or custom-cut shapes prepared to exact specifications.

At A-1 Alloys, we take pride in being a trusted partner in the aluminum industry, providing customers with high-quality materials, precise processing, and dependable service. Our focus on aluminum allows us to deliver a wide range of grades, forms, and sizes to meet the unique needs of industries that rely on strength, durability, and lightweight performance.

At Champagne Metals, we are dedicated to delivering premium aluminum products and solutions designed to meet the diverse needs of our clients. Our expertise spans a broad spectrum of aluminum offerings, including extrusions, fabricated components, and custom profiles tailored to specific requirements.

More Aluminum Bars Manufacturers

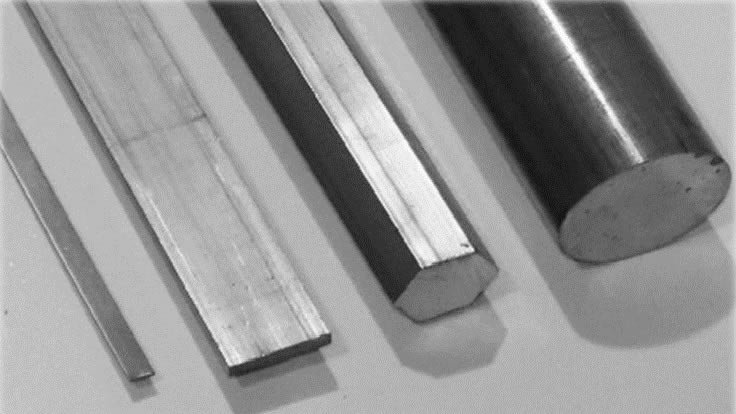

Aluminum suppliers make many aluminum shapes available to their clients. Patrons of aluminum suppliers make use of aluminum shapes for many purposes. Because of this diversity of products and applications, it is impossible to arrest an all-encompassing definition of an aluminum bar and its applications.

Generally speaking, an aluminum bar is any simple aluminum shape that is characterized by a longer length than width. Such a shape can be round or polygonal; an aluminum bar's shape depends on its intended application. For example, an aluminum bar that has just emerged from a primary supplier is not likely to be ready for use. Instead, it is likely to be shipped to a metalworking or forging operation where it will be shaped into something usable.

On the other hand, aluminum bars that have emerged from metal shaping processes can be useful; such products are often used to make railings, stakes and tines. Such bars are often referred to as rods.

The word "billet" is more commonly used to refer to raw industrial ingredients. Billets made from aluminum, which are semi-finished bar stock, go through extrusion to become bar-shaped. They are heated to 900°F, placed in an extrusion press and drawn.

Drawing refers to pushing the billet through a steel die by a large, hard metal ram under pressure. They are often pushed through consecutively smaller dies multiple times in order to reduce their cross section a little at a time.

Larger bars may only be extruded once, while small bars are often put through the process more than twice. Liquid nitrogen is often poured after the bar is extruded to cool the material. Once the material has cooled, it can be shipped to customers or sent for further processing. Although many bars require no sort of cold working, those that are often exhibit an improved surface finish and dimensional tolerances.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services