Time is money, and we save you both. We don’t mess around when it comes to precious time, and we offer the highest quality aluminum products that other companies don’t stock. We make a point of keeping products on-hand that other companies will not, because it is our goal to make your experience with us painless and fulfilling. Visit our website or call us today to learn more!

At DIX Metals, Inc., we pride ourselves on being a leading innovator in the aluminum industry, dedicated to delivering exceptional products and services tailored to meet diverse needs. We specialize in crafting high-quality aluminum and stainless steel products, ranging from precision extrusions to custom fabrications that cater to a wide array of industries, including automotive, aerospace, and...

At Marmon/Keystone LLC, we stand at the forefront of the aluminum industry, dedicated to delivering unparalleled products and services that cater to a wide array of needs. Our extensive range of aluminum solutions is crafted with precision to meet the diverse requirements of our clients, whether they are engaged in manufacturing, construction, or other industrial applications.

At Kenig Aerospace, we are at the forefront of aerospace innovation, specializing in the precision engineering of aluminum components that drive excellence in the aerospace industry. Our extensive experience allows us to deliver superior products that meet the rigorous demands of aerospace applications. We are dedicated to crafting high-quality aluminum parts and assemblies that enhance...

More 6061 Aluminum Manufacturers

A heat-treatable moderate to high strength aluminum alloy with toughness greater than 6005A is 6061. Despite having less toughness in the weld zone, it offers excellent weldability and strong corrosion resistance. In addition, it is moderately resilient to tiredness. T4 temper offers good cold formability; T6 temper has limited formability. Ineffective for extremely detailed cross-sections.

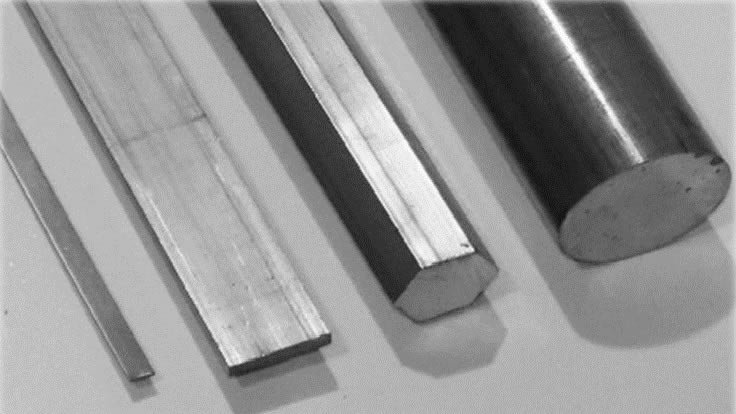

A popular type of alloyed aluminum is 6061 aluminum. After aluminum, silicon and magnesium make up the majority of their composition. This all-purpose metal can be extruded, annealed, cold worked and heat treated, and weldable. Instead of being cast, it is typically delivered in billet form.

The Production of 6061 Aluminum

The alloying procedure can start once the composition has been decided. First, billets are formed by cold processing that does not heat the metal at or above its recrystallization temperature after the pure aluminum is fused with magnesium and silicone. Then, it can be manufactured using various techniques, including rolling, extruding, and forging.

Following cold working, 6061 aluminum undergoes several heat-treating procedures, including annealing and solution heat treatments. These increase the metal's capacity to be worked, stabilize its physical characteristics, strengthen its mechanical qualities, and harden its surface. For 6061 aluminum, a common heat treatment technique is T61. This procedure enhances tensile strength and fatigue resistance.

Physical Properties of 6061 Aluminum

Type 6061 aluminum is a member of the 6xxx family of aluminum alloys, which includes materials where silicon and magnesium are the main alloying constituents. The second digit represents the level of base aluminum impurity control. If this second number is a "0," it means that most of the alloy is industrial aluminum with the same impurity levels as before and that no additional caution is required to tighten controls.

The fourth and third digits are only placeholders for specific alloy designations. Type 6061 aluminum has a nominal composition of 97.9% Al, 0.6% Si, 1.0% Mg, 0.2% Cr, and 0.28% Cu. Aluminum alloy 6061 has a density of 2.7 g/cm3. The 6061 aluminum alloy may be heat treated, is simple to shape, is weldable, and has strong corrosion resistance.

Mechanical Properties of 6061 Aluminum

How 6061 aluminum alloy is heat treated or strengthened through the tempering process affects its mechanical qualities. The strength ratings for the alloy will be derived from 6061-T6, a commonly used temper for the aluminum sheet and bar stock. Its moduli are 26 GPA, while its elasticity modulus is 68.9 GPA (3770 ksi).

This alloy is typically simple to weld together and easily deforms into most needed forms, making it a flexible production material. Yield and tensile strength are essential components when evaluating mechanical attributes. The yield strength describes the maximum stress required to distort the part in a specific loading configuration elastically.

On the other hand, the maximum stress a body can endure before breaking is known as its ultimate load. According to industry standard design procedures, the ultimate tensile strength is the most significant design restriction for static applications; nevertheless, it can be useful for some applications that require it. For example, the ultimate yield strength of 6061 aluminum alloy is 276 MPa (40000 psi), while its ultimate tensile strength is 310 MPa (45000 psi).

The capability of a substance to withstand being sheared by rival factions along a plane, much like scissor tears through paper, is known as shear strength. The paper fails "in shear" as the twin scissor blades come together due to the opposing forces acting on the paper's cross-sectional plane. This number is helpful in torsional uses (shafts, bars, etc.) when twisting might result in this type of shear stress on a material.

Applications of 6061 Aluminum

One of the various aluminum alloys that aluminum suppliers provide is aluminum 6061. As with other metals, aluminum is frequently alloyed with other substances to improve its properties. Excellent corrosion tolerance and a max tensile ratio are two advantages of 6061 aluminum. In addition to being utilized in manufacturing furniture, automobiles, aircraft, and a wide range of other commercial and consumer products, it can be produced into tubes, rods, and pipes. Among the heat-treated alloys, this is one of the more adaptable ones.

6061 aluminum is widely used in various industries, including automobiles, aerospace, engineering, and manufacturing. The manufacture of trucks and marine vessels, the building of pipelines, the fabrication of substantial structural components, and the construction of tanks can all include this type of aluminum. It is perfect for creating all sorts of items since it is simple to machine, cut, stamp, bend, spin, and drill. Due to its durability and outstanding corrosion resistance, it is frequently used for floors, ramps, and steps.

Choosing the Proper 6061 Aluminum Supplier

To make sure you have the most positive outcome when purchasing 6061 Aluminum from a 6061 Aluminum Supplier, it is important to compare at least 4 or 5 Suppliers using our list of 6061 Aluminum suppliers. Each 6061 Aluminum Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each 6061 Aluminum business website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple 6061 Aluminum businesses with the same quote.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services