Time is money, and we save you both. We don’t mess around when it comes to precious time, and we offer the highest quality aluminum products that other companies don’t stock. We make a point of keeping products on-hand that other companies will not, because it is our goal to make your experience with us painless and fulfilling. Visit our website or call us today to learn more!

At Alliant Metals, we take pride in being a trusted source for high-quality aluminum products that meet the demands of a wide range of industries. Our work revolves around providing precision-cut aluminum in the form that best serves our customers, whether that means sheets, plates, bars, or custom-cut shapes prepared to exact specifications.

At A-1 Alloys, we take pride in being a trusted partner in the aluminum industry, providing customers with high-quality materials, precise processing, and dependable service. Our focus on aluminum allows us to deliver a wide range of grades, forms, and sizes to meet the unique needs of industries that rely on strength, durability, and lightweight performance.

At Champagne Metals, we are dedicated to delivering premium aluminum products and solutions designed to meet the diverse needs of our clients. Our expertise spans a broad spectrum of aluminum offerings, including extrusions, fabricated components, and custom profiles tailored to specific requirements.

More 7075 Aluminum Manufacturers

7075 aluminum alloy is widely recognized in the metals industry as a premier high-strength material, and is frequently compared in performance to many steel alloys. Its exceptional strength-to-weight ratio, low density, and machinability make it a preferred choice for critical, highly-stressed structural components across a diverse range of industries. The unique properties of 7075 aluminum stem primarily from its high zinc content, with magnesium, copper, and chromium also contributing to its superior performance characteristics. If you are seeking a material that can deliver both strength and lightweight efficiency, 7075 aluminum is an industry benchmark worth considering.

While 7075 aluminum boasts exceptional strength, it is important to note that it does not offer the same level of machinability or weldability as some other common aluminum alloys, such as 6061 or 2024. Additionally, compared to other aluminum alloys, 7075 exhibits somewhat lower corrosion resistance. Buyers and engineers should carefully evaluate these trade-offs based on their specific application requirements.

What is 7075 Aluminum? Key Properties and Chemical Composition

7075 aluminum belongs to the 7xxx series of aluminum alloys, which are characterized by the addition of zinc as the principal alloying element. This alloy typically consists of approximately 90% aluminum, 5.6% zinc, 2.5% magnesium, and 1.6% copper, with trace amounts of chromium, iron, silicon, manganese, and titanium. The result is a metal with a density of about 0.102 pounds per cubic inch (2.81 g/cm³), delivering tremendous yield and tensile strength while remaining significantly lighter than steel.

Some notable mechanical properties of 7075 aluminum include:

- Tensile strength: Up to 83,000 psi (T6 temper)

- Yield strength: Up to 73,000 psi (T6 temper)

- Brinell hardness: 150 (T6 temper)

- Excellent fatigue resistance and high stress corrosion resistance (notably in T7351 and T173 tempers)

- Good thermal conductivity and moderate electrical conductivity

Curious about how 7075 aluminum compares to other alloys? Compare 7075 vs. 6061 aluminum or 7075 vs. titanium for specific aerospace and engineering applications using our detailed materials comparison guides.

How is 7075 Aluminum Processed and Manufactured?

What steps are involved in turning raw materials into finished 7075 aluminum products? The production of 7075 aluminum alloy is a multi-stage process designed to optimize its strength and performance. Here’s a closer look at the process:

- Alloying: Pure aluminum is combined with zinc (the main alloying element), as well as magnesium, copper, and trace elements like chromium. These ingredients are melted together at high temperatures to achieve a uniform composition.

- Direct Chill (DC) Casting: The molten alloy is poured into a vertical mold, initiating solidification at the base (direct chill). Continuous cooling is applied using a water film, which extracts around 80% of the heat, while the rest is conducted through the mold walls. This semi-continuous casting method results in solid billets or aluminum bars with tightly controlled microstructure and minimal defects.

- Secondary Processing: The solidified billets undergo further processing such as hot rolling, forging, or extrusion. These steps refine the grain structure, enhance strength, and shape the material into forms suitable for various industrial needs, including plates, sheets, rods, and custom profiles.

- Heat Treatment: 7075 aluminum is typically subjected to solution heat treatment and aging (such as T6 or T73 tempers), which further increases its mechanical strength and tailors its performance for specific applications.

The advanced metallurgy and precise thermal processing of 7075 aluminum are what give it the edge over other materials in demanding environments. If you are interested in learning more about the manufacturing process of high-strength aluminum alloys, browse our in-depth resources or request a manufacturing consultation.

Advantages and Benefits of 7075 Aluminum Alloy

Why do engineers and manufacturers choose 7075 aluminum over other grades? Here’s a comprehensive look at its advantages:

- Superior strength-to-weight ratio: 7075 aluminum is among the strongest commercially available aluminum alloys, with mechanical properties rivaling those of certain steels. This makes it ideal for load-bearing and structural applications where minimizing weight is critical.

- Lightweight construction: With a density significantly lower than steel, 7075 aluminum delivers substantial weight savings—an essential factor in aerospace, automotive, and sports equipment manufacturing.

- High fatigue resistance: The alloy’s microstructure and tempering processes afford outstanding resistance to cyclic loading, ensuring long-term reliability in dynamic, high-stress environments.

- Good corrosion resistance: While not as corrosion-resistant as some other aluminum grades (e.g., 6061 or 5052), 7075 offers satisfactory protection in most environments, especially in T73 or T7351 tempers, which are optimized for stress corrosion resistance.

- Excellent machinability: Despite its high strength, 7075 aluminum can be precisely machined to tight tolerances, making it suitable for complex parts requiring accurate dimensions and fine surface finishes.

- Aesthetic finish: The alloy’s natural reflectivity and ability to take on a high polish often eliminate the need for additional surface treatments, enhancing both functional and visual appeal in finished products.

- Wide availability: 7075 aluminum is available in a variety of tempers (T6, T651, T73, T7351, T76, T7651) and product forms (bar, plate, sheet, extruded shapes), allowing buyers to select the most appropriate configuration for their application.

- Proven performance in critical applications: From sheet metal for aircraft skins to machined components for defense and sporting goods, 7075 aluminum’s track record is unmatched.

7075 Aluminum vs. Other Alloys: How Does It Compare?

When selecting a material for high-performance applications, buyers often ask:

- Is 7075 aluminum stronger than 6061? Yes, 7075 is significantly stronger and is typically used where strength is the primary requirement.

- Can 7075 aluminum be welded? While possible, welding is challenging due to increased risk of cracking; alternative joining methods are usually recommended.

- Does 7075 aluminum resist corrosion as well as 5052 or 6061? 7075 offers good corrosion resistance, especially in certain tempers, but is less resistant than marine-grade alloys like 5052.

- What are the main applications for 7075 aluminum? See below for an extensive list of common uses across industries.

Applications and Use Cases for 7075 Aluminum Alloy

The unique blend of high strength, light weight, and fatigue resistance makes 7075 aluminum a top choice for demanding applications across multiple industries. Explore how leading manufacturers and engineers leverage 7075 aluminum for superior performance:

- Aerospace and Aviation: 7075 aluminum is a staple material in aircraft manufacturing, used for structural airframe parts, wing spars, fuselage frames, bulkheads, landing gear components, and more. Its ability to withstand high stresses and fatigue loads at elevated altitudes makes it indispensable for both commercial and military aircraft.

- Automotive and Motorsports: Performance vehicles and race cars utilize 7075 aluminum for high-stress components such as suspension parts, drive shafts, transmission gears, and wheel hubs. The alloy’s combination of strength and weight reduction improves acceleration, handling, and fuel efficiency.

- Defense and Firearms: 7075 is widely used in military and tactical equipment. Notably, the receivers and frames of M16 rifles and other small arms are often machined from 7075 due to its toughness and reliability under combat conditions.

- Sports and Recreation: High-end sporting goods—including bicycle frames, rock climbing equipment, archery components, and golf club heads—commonly feature 7075 aluminum for its lightweight durability and resistance to deformation.

- Industrial and Tooling: Heavy-duty molds for plastic injection, high-strength gears, and critical machine components are frequently produced from 7075 aluminum to ensure dimensional stability and long service life under repeated loading.

- Marine and Transportation: While not as corrosion-resistant as 5xxx series alloys, 7075 aluminum is nonetheless used in select marine and transportation applications where high strength is essential and corrosion can be managed with protective coatings.

- Consumer Electronics and Custom Fabrication: The alloy’s machinability and attractive finish lend themselves to premium housings, brackets, and structural parts in electronics and custom projects.

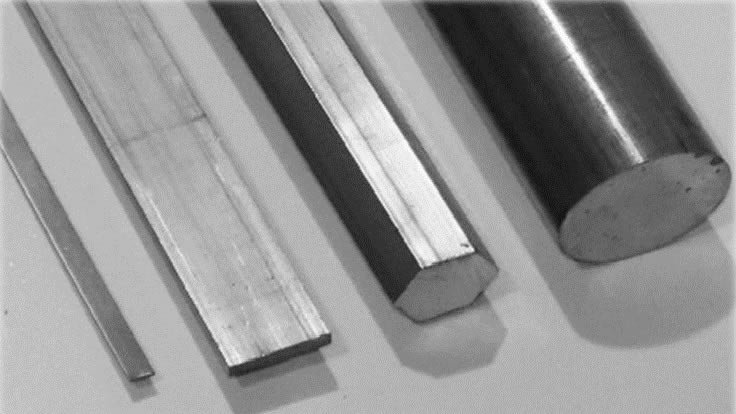

Common Product Forms of 7075 Aluminum

Looking for a specific format of 7075 aluminum for your project? This versatile alloy is widely available as:

- 7075 aluminum plate (thick gauge, ideal for structural and tooling applications)

- 7075 aluminum sheet (thin gauge, used for skins, covers, and lightweight panels)

- 7075 aluminum bar (round, square, and flat, for machining precision parts)

- 7075 aluminum rod (cylindrical forms for shafts and pins)

- 7075 aluminum tubing (hollow forms for frames, sporting goods, and aerospace)

- Extruded and forged shapes (custom profiles for specialized applications)

Not sure which form is best for your application? Contact a 7075 aluminum supplier or request a sample to compare machinability and finish in your actual production environment.

Factors to Consider When Buying 7075 Aluminum

When sourcing 7075 aluminum for your manufacturing or engineering needs, it’s essential to evaluate several key decision factors to ensure optimal performance, value, and supply chain reliability. Here are important considerations to keep in mind:

- Required temper and mechanical properties: Determine whether your application demands maximum strength (T6), increased stress corrosion resistance (T73 or T7351), or specific fatigue life characteristics.

- Form factor and dimensions: Specify whether you need 7075 in plate, sheet, bar, rod, or custom extrusions. Confirm standard sizing and tolerances with your supplier.

- Certification and traceability: For aerospace, defense, and critical engineering applications, ensure your material comes with full mill test reports (MTRs), quality certifications (e.g., ASTM B209, AMS 4045), and traceability documentation.

- Secondary processing needs: Consider if you require pre-machined blanks, custom cuts, surface treatments (anodizing, chromate conversion), or finished assemblies.

- Corrosion protection: If your operating environment is highly corrosive, discuss additional coatings or treatments with your supplier.

- Supplier reputation and support: Choose a supplier with a proven track record in supplying high-strength aluminum alloys, responsive technical support, and the ability to fulfill both small and large orders reliably.

Frequently Asked Questions About 7075 Aluminum

How much does 7075 aluminum cost compared to 6061? 7075 aluminum typically commands a premium over 6061 due to its superior strength and more complex production processes. However, its higher performance often justifies the added expense for critical applications.

Is 7075 aluminum suitable for welding? Welding 7075 is challenging due to its susceptibility to hot cracking and reduced strength in the heat-affected zone. Mechanical fastening or adhesive bonding is generally recommended for joining.

What are the main alternatives to 7075 aluminum? Alternatives include 2024 aluminum (noted for high fatigue resistance), 6061 aluminum (for better weldability and corrosion resistance), and titanium (for extreme strength and corrosion resistance, at a higher cost).

Which tempers are most commonly used for 7075 aluminum? The most common tempers are T6 (for maximum strength), T651 (stress-relieved), T73, and T7351 (for enhanced stress corrosion resistance).

How to Choose the Best 7075 Aluminum Supplier for Your Project

To ensure the most successful outcome when purchasing 7075 aluminum, it’s crucial to compare multiple reputable suppliers. Here’s a step-by-step approach to finding the right partner for your needs:

- Identify qualified manufacturers: Use our curated list of 7075 aluminum manufacturers to find companies with the capabilities and certifications required for your application.

- Review business profiles: Each supplier’s profile details their areas of expertise, available product forms, and technical support offerings.

- Compare pricing and lead times: Request quotes using our RFQ form to evaluate cost, minimum order quantities, and delivery schedules from multiple vendors.

- Evaluate technical support: Directly contact suppliers to discuss your specific requirements, request material samples, and verify certifications.

- Check references and reputation: Research customer reviews, case studies, and industry partnerships to assess supplier reliability.

Ready to source high-strength 7075 aluminum for your next project? Browse our directory of 7075 aluminum suppliers or request a competitive quote today.

Conclusion: Is 7075 Aluminum Right for Your Application?

7075 aluminum alloy stands out as one of the strongest and most reliable materials available for structural and high-performance engineering applications. Its unique combination of strength, low weight, fatigue resistance, and machinability makes it the preferred choice for aerospace, automotive, defense, sporting goods, and industrial manufacturing. While it does have limitations in weldability and corrosion resistance compared to other alloys, these are often outweighed by its outstanding mechanical properties.

When evaluating materials for your next project, consider the specific demands of your application—load requirements, operating environments, fabrication needs, and cost constraints. Consult with experienced aluminum suppliers and engineers to determine if 7075 aluminum is your best solution.

Explore More About Aluminum Alloys

- Types of Aluminum Bars: Grades, Applications, and Selection Guide

- Aluminum Sheet Grades and Their Applications

- Contact Leading Aluminum Manufacturers

Need expert advice on selecting or sourcing 7075 aluminum? Reach out to our team of materials specialists or explore our comprehensive resources on aluminum alloys to make the most informed decision for your project.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services